Case Study

Anti-Sweat Door Heater Controls: What Works, and What Works Best?

Study conducted by Vermont Energy Investment Corporation

Reach-in cooler and freezer cases work hard, and they sweat. Stores install anti-sweat door heaters in the doors and frames of these cases to keep the glass from fogging up. These anti-sweat door heaters increase the refrigeration load in the case, which in tandem with the electric resistance heaters themselves can dramatically increase energy costs. Stores can install controls to cycle or pulse the heaters on as needed, rather than running them 24/7.

How do you maximize energy savings while making sure your customers can see what’s behind the glass?

This study describes several anti sweat door heater control strategies and products designed to optimize anti-sweat door heaters. We will review each strategy, exploring their energy and maintenance implications, as well as what option can work best for your store. The savings are real, and you’ll learn the most effective way to grab them.

For this study, VEIC used a Vermont Hannaford Store installed with ControlTec’s AS-20 system and a panel type system. Data from both systems can be found in the results at the end of this page. The AS-20 system controls anti-sweat door heaters on a case-by-case basis with the use of sensors, while a panel type system controls every case based on 1 sensor or “pulse” setting. The case study proves that ControlTec’s case-by-case method of controlling anti-sweat heaters overwhelming outperformed the panel type, 1 sensor system.

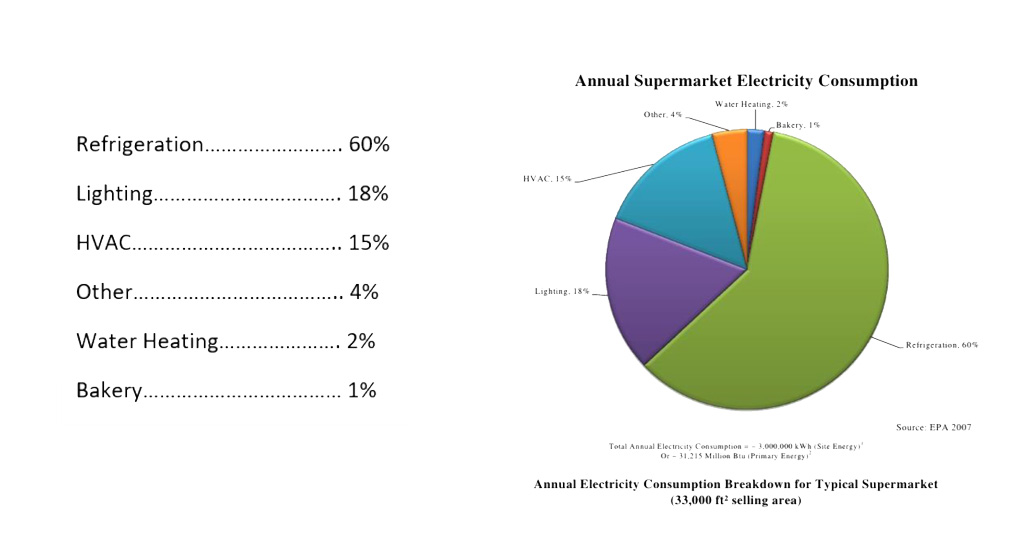

Supermarket Energy Consumption

Anti-Sweat Heaters Background Knowledge

Why Use Anti-Sweat Door Heaters?

Anti-sweat door heaters are used to keep the glass on the glass display door clear of fog and condensation. Doors need to be clear so that customers can easily and clearly view the product through the door. The anti-sweat door heaters also prevent water/mold from getting into the refrigeration cases. In turn, this ensures longevity of door frames and mullions. Lastly, if doors are sweating/condensating it creates a safety hazard in the store if the floor around the cases then become wet and slippery.

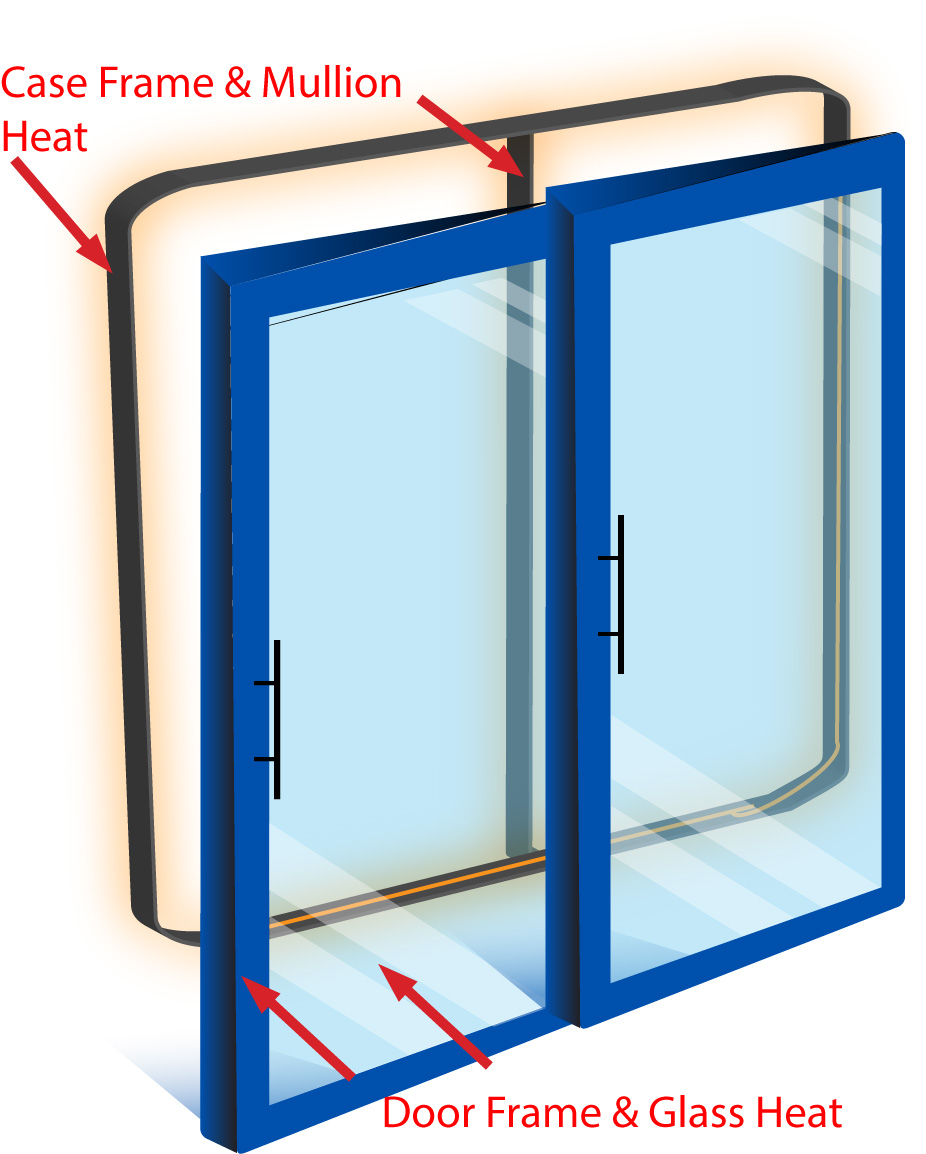

Where is the Heat?

The heat is located in multiple door components in most cases. Heat is always located in the case frame and often located in the door frame and door glass.

Why Do We Care?

Typical grocery stores contain 75-150+ freezer and cooler doors. With no controls these heaters cost $15,000 – $30,000+ / store / year. These heaters typically cost around $200/year per door to heat with no controls.

Anti-Sweat Control Strategies

Anti-Sweat Heater Savings via Scheduling

With this method anti-sweat heaters are scheduled to turn on and off at certain times of the day. While this method may be inexpensive, there is no certainty that this control is preventing sweating or condensation on glass display doors. Store managers are required to be extremely engaged and also required to monitor the cases constantly in this method. Therefore, there is no way of telling if this system has been overridden without sending a technician to the store. Savings are difficult, if not impossible to measure with this method.

Anti-Sweat Heater Cycling

This method cycles anti-sweat heaters on certain intervals instead of scheduled times. Like the above method, this does not ensure cases are not sweating and requires a lot of attention from stores managers. There is also no way of telling if this type of system has been overridden. Heaters will be cycled as 15 mins on, 45 mins off in the winter months and 15 mins on, 15 mins off in summer months so savings reflect those cycles.

Anti-Sweat Heater Cycling via Store Humidistat

This method involves cycling all cases based on the readings from one location in the store making savings highly dependent on dehumidification control from the HVAC system. This method is only effective if every case in the store has adequate anti-sweat heaters. If there is one bad/weak heater in the store, the system can only save as much as the weakest case which decreases savings drastically. Savings vary drastically based on location and case conditions. Savings range from 10-40% off time.

Anti-Sweat Heater Cycling via Case Dew Point (w/ ControlTec AS-20 System)

ControlTec AS-20’s method uses frame temperature and dew point sensors to analyze store conditions directly outside the case for every case in the store. Based on the ambient conditions outside each case, the AS-20 system determines the required temperature of doors and frames and cycles anti-sweat heaters accordingly to prevent condensation. ControlTec's method is controlled on a case-by case basis rather than store-wide. Savings range from 40 – 90% off time, making this method the most profitable and reliable.

Anti-Sweat Heater Savings Persistence

Typical persistence of savings is low because with almost every system, there is no easy way to tell if controls have been overridden. Many controls are overridden by a technician after installation. ControlTec AS-20’s System is connected to the IoT (Internet of Things) which provides a unique advantage of knowing when the controls have been overridden and can schedule a technician to reconnect. Most other systems become obsolete when overridden.

Test Store (Hannaford Metered Savings Results)

Hannaford Metered Savings Results

VEIC administered a test study at a Hannaford Supermarket in Vermont using 2 different systems. The first being a whole store, 1 humidistat system (panel type) and the second being the case by case method (ControlTec AS-20 System).

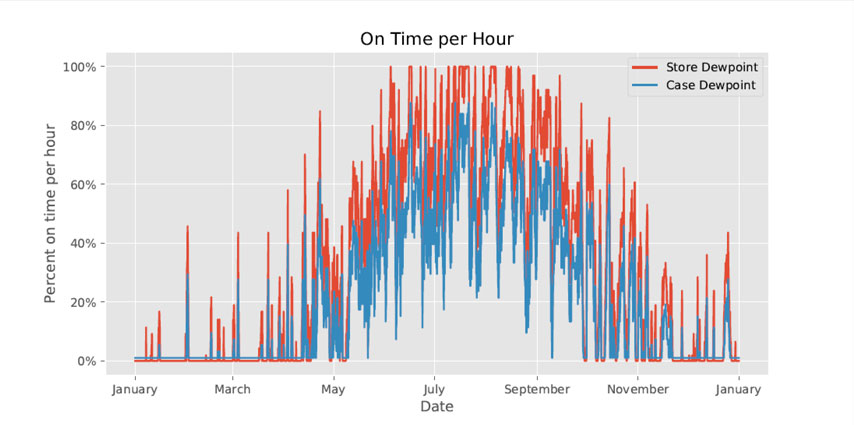

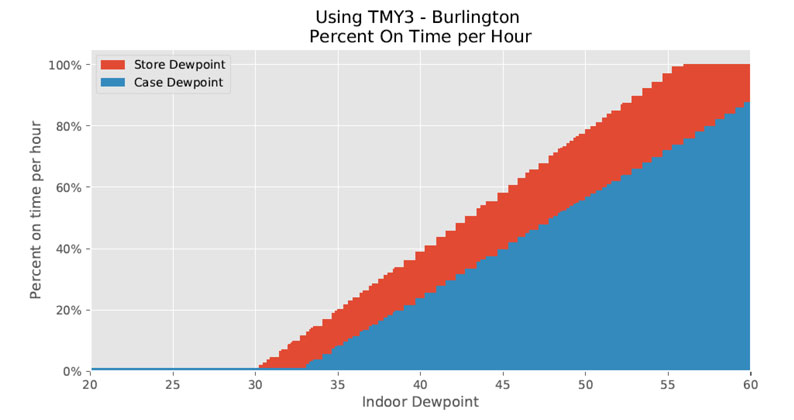

Result Graphs

In the graphs red represents the store dew point method and blue represents case by case method (AS-20 System)

Incremental Results (1 Sensor Panel Type vs ControlTec AS-20)

In this Hannaford store, the AS-20 System proved to save 32% more than the panel type, 1 humidistat system. The case by case method (AS-20 system) saved over $110/door annually in this case study, making it the highest saving method by a significant margin.